After graduating from the prestigious

in 2019 with a degree in environmental economics, Mansi Jain returned to India to uncover opportunities in this space that could be transformative from both a problem-solving and entrepreneurial perspective.

She didn’t have to look any further than her father Rajesh Jain, a graduate of chemical engineering from the , who had spent the last 25 years in the water and energy industry developing hundreds of water treatment facilities across India.

Speaking to The Better India, Mansi recalls, “Incidentally, my father had been an engineer in the water and energy industry for over 25 years, and designed as well as operated over 400 wastewater treatment facilities in India with the consistent takeaway that 75% of these facilities failed operationally even though they were key to the local water ecosystem.”

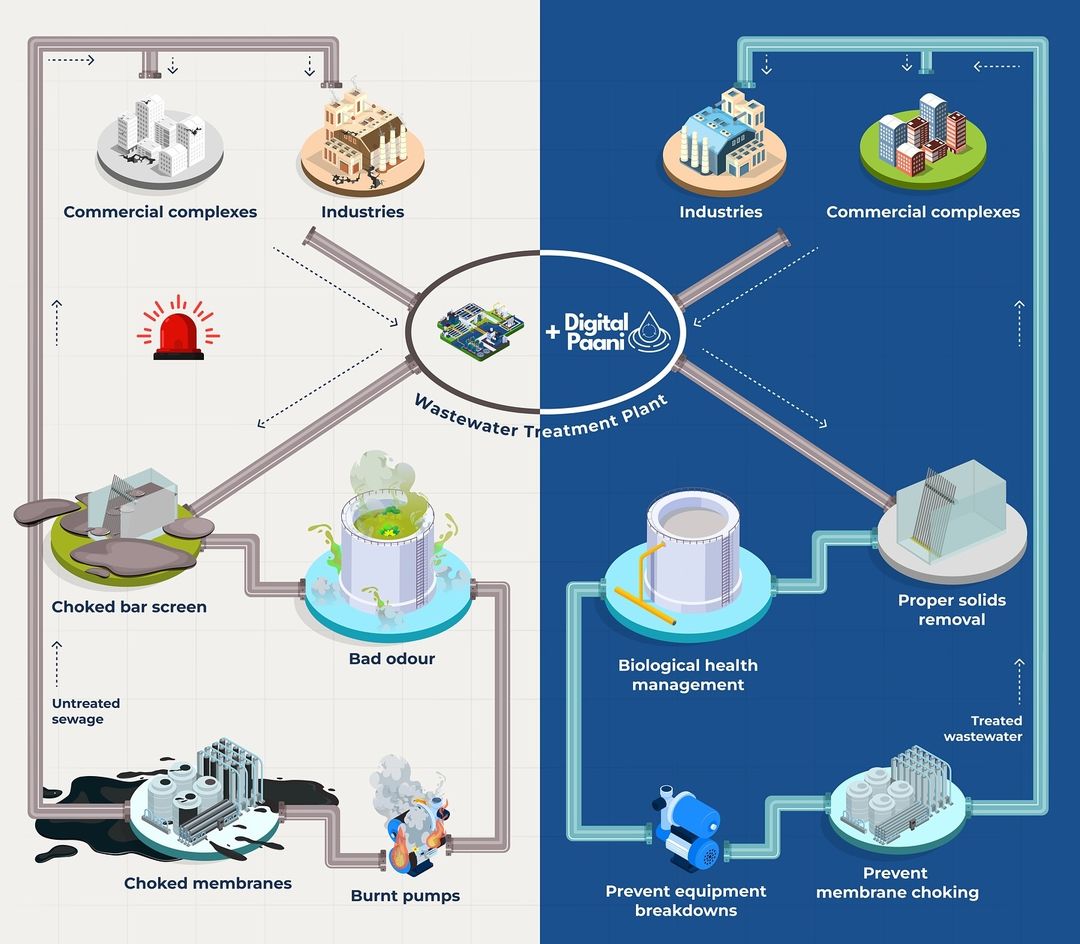

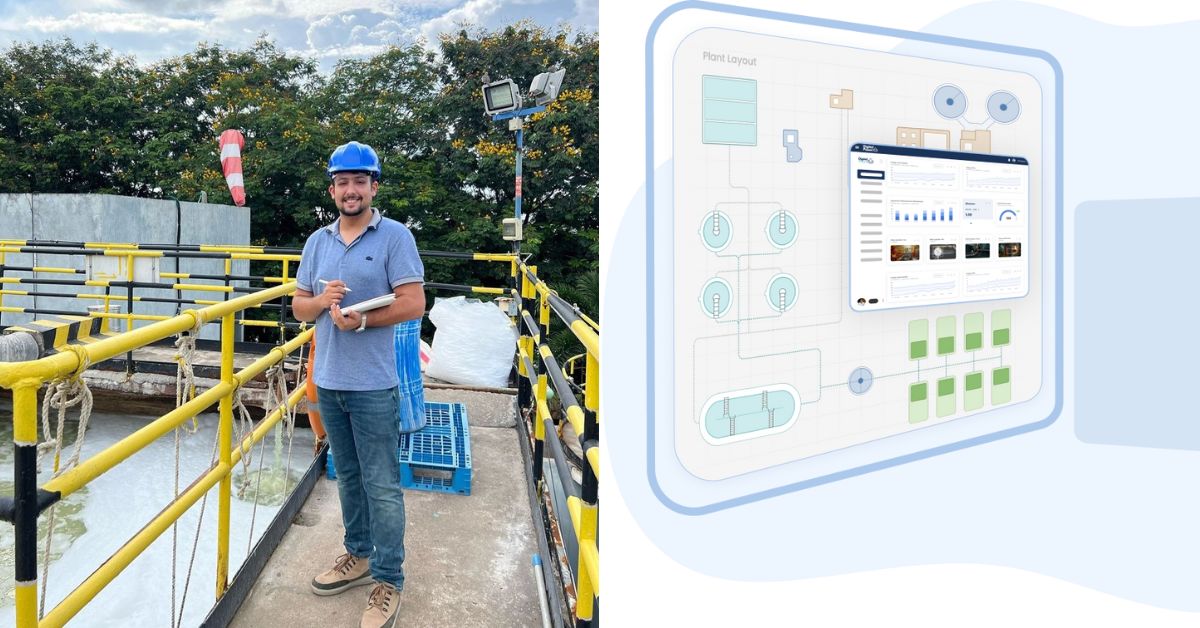

Managing Water Treatment Infrastructure: Mansi Jain, co-founder of Digital Paani

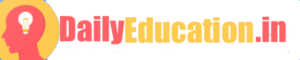

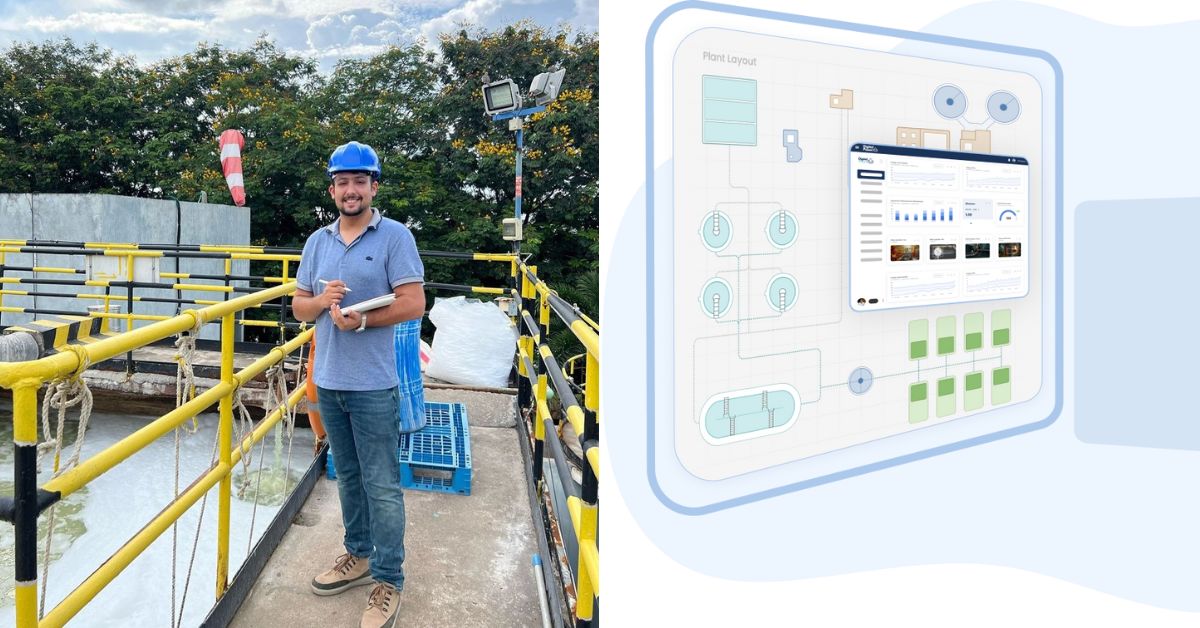

According to Mansi, most of these plants don’t work in the long run for a variety of reasons including biological disturbance, equipment failure like burnt pumps, or the choking of membrane filters that act as a barrier to separate contaminants from the water.

So, is there a way for these plants to anticipate these problems and fix them in advance to improve their efficiency and longevity? Suffice it to say that there are a variety of today that are developing technological solutions for wastewater management.

“India has about 90,000 installed wastewater treatment plants. But today 95% of the market is managed entirely manually by deploying operators in each plant. This has several drawbacks; problems are detected about three weeks late after breakdowns and operators lack the expertise to tackle problems. Other technologies in the market only make dents in part of the problem; they only monitor data or automate the key equipment like pumps,” she says.

After months of brainstorming to understand how they can solve this problem in a scalable manner, they started Digital Paani in end 2020, piloted an IoT-enabled software that manages end-to-end operations of a water treatment plant, and saw “incredible results”.

Digital Paani is helping buildings and industries move towards water neutrality and reduce water losses across their campus. To do this, Digital Paani works in a stepwise manner:

1) Maximise recycling by ensuring wastewater infrastructure is working well.

2) Helping industries and residential societies do water accounting real-time, know where they are having water losses, and provide roadmaps to reduce those losses.

3) Actually reducing those losses by providing operational excellence and management through technology for key assets contributing to water losses such as cooling towers.

In other words, Digital Paani is a water management platform that tracks and manages a water treatment plant’s health and performs tasks like equipment automation, providing WhatsApp updates to users, and guiding process management.

By offering real-time insights, complete control, and 24/7 management with actionable recommendations, they drive operational excellence for sustainable water management.

As Mansi explains, “Think of our platform as a doctor for water infrastructure, telling buildings what’s wrong with their infrastructure and what it needs, as well as providing the medicine to fix it, whether it’s directing technicians on about the right amount of chemical dosage required, automating equipment to function properly or directing operators on the best next steps. Through our work, we help clients save crores in fines, but more importantly, they recycle their wastewater — 90 million litres of wastewater is treated daily at plants associated with us.”

At present, over 40 industry giants, including Tata Power, Delhi Jal Board, Britannia, and Leela Hotels, are using the Gurugram-based startup’s technology.

Understanding the elements that Digital Paani works with to address their water treatment needs.

“Once we log in design inputs about the infrastructure into our software, we create standard operating procedures for operating the plant in real-time. Our client can visualise the asset (wastewater treatment plant) and can gauge its analytics from how much wastewater is getting treated to the quality of treatment being achieved and whether the equipment is functioning properly or not,” said Mansi during an episode of in April 2024.

“In other words, the client has a complete online software before them to visualise their asset. If there is a problem inside the plant, our software can assess and interpret data using AI to detect it. The best part is that clients don’t even have to be on our software to manage these issues. Management actions are happening automatically, whether through equipment control or by telling operators directly what to do. Clients just receive alert notifications on their WhatsApp number to make things easy,” she added.

Their product innovation, Mansi argues, also allows them to unlock business model innovation. “Instead of becoming an add-on cost for facilities like our competitors, we can de-risk adoption and offer guaranteed savings through two models which no one else in the market can do,” says Mansi, speaking to The Better India.

“First, we enable plant owners to manage plants using their under-utilised staff like electricians with our system and team’s remote management rather than outsourcing operations for lack of expertise. This allows them to save up to 66% of operating costs,” she adds.

Second, as Rajesh notes, “We take the entire operations contract of a facility and allow service provider partners that provide physical services like operators onsite to manage clusters of plants as a fleet with a small common workforce rather than individual deployments.”

Digital Paani “integrates every aspect of wastewater treatment operations and scales the expertise needed to handle facilities” in three steps.

1) First, it ‘knows’ the needs of the plants by determining how each facility should operate given its unique physical configuration and needs. “We do this by doing a design assessment of each facility on our software as well as capturing operations information from each unit operation in a facility. This data spans a wide range, from using computer vision to look at biological process health, to looking at electrical data, energy data, pressure, vibration, flow, etc,” says Mansi.

2) Second, it ‘tells’ the need to the relevant stakeholders by offering complete visibility through WhatsApp and live dashboards.

3) Finally, it ‘solves’ the need by executing the required actions directly through automated workflows, whether it is training onsite teams, guiding their daily workflow and validating their work or managing the physical operation of equipment through our in-platform automation manager. When things start going wrong, it uses data streams from onsite sensors and electrical panels to diagnose the root cause of the issue and drive issue closure.

“We even recommend operational and physical improvements. This approach has transformed defunct facilities while reducing their costs by up to 66%,” claims Rajesh.

Digital Paani looks to understand the physical water treatment infrastructure and develops unique tools to manage it.

Mansi argues that every building and factory can rely on local and renewable wastewater for up to 90% of their water needs, a vital response to amid climate change. Unfortunately, as she stated earlier in this article, about 75% of treatment facilities end up dysfunctional because operations are manual and reactive, and the expertise and skills needed to manage such complex operations don’t exist at the ground level.

“We’re solving the above issue by reimagining this industry through Digital Paani, which effectively scales the needed technical expertise to drive operational excellence in facilities. This results in the transformation of non or low-functioning plants to high-quality, compliant units treating 100% of water to high-water-quality standards, all while reducing operating costs by up to 30%. Many of our customers have been able to reduce breakdowns significantly (up to 85%) and reduce energy consumption in the range of 20 to 35%,” she claims.

“Most importantly, they can now confidently reuse this water; many of our customers have gone from reusing 45% of their water on average to around 80%. This is why major players in the industry are adopting our technology,” she adds.

Moreover, as Mansi notes, the ease of integrating Digital Paani, which functions on a plug-and-play model, “further enhances its appeal”. Treatment facilities of any size and type can be installed in three straightforward steps:

1) Site survey

2) [Parallel] Any IoT deployment needed on the ground

3) [Parallel] Plant onboarding onto our software

“This whole process only takes 30 to 45 days,” she says.

Besides industries, Digital Paani has also made forays into the residential sector.

“We provide continuous expertise for regular operations as well as guidance on the needed retrofits so that they can get their STP completely streamlined and treat and reuse their water. We have converted many residential STPs from dysfunctional to reusing 70% of water in flushing, horticulture, and more. Many customers used to receive notices and fines from the Pollution Control Board earlier because they were unable to manage their operations, and we have solved that for good,” she claims.

“Our software is highly flexible, featuring comprehensive configuration panels that simplify the integration of plants of different sizes and technologies. On the backend, we have onboarded each key unit operation in water management, be it biological treatment, chemical treatment, RO systems, UF systems or more, so when we onboard a new unit, we simply tick that module and get the relevant analytics, automation flows, alerts, and so on,” says Rajesh.

“This makes it easy to adapt to facilities of all kinds. Moreover, our team is well-equipped to provide expert support for any plant management as required. For instance, at present, we serve diverse needs including STP management for Taj Hotels, ETP management for Britannia, total water management for Plaksha University, and a 70 MLD STP in Dwarka, Delhi,” he adds.

Mansi Jain and her father Rajesh recently appeared on Shark Tank India.

Digital Paani is currently operational in about 14 states and has raised about $1.2 million from global investors like Elemental Excelerator and Echo River Capital as well as Indian investors like Enzia, Peer Cheque, SAE, DevC, Bharat Founders Fund, and leading angels like Ashish Goel (Urban Ladder), Yamini Bhatt (Wymo) and Mohit Tandon (Delhivery).

As Karuna Jain and Shivam Jindal of Enzia Ventures, a venture capital fund, in the startup, “Digital Paani’s solution seamlessly integrates into existing facilities, analysing the infrastructure’s needs based on multiple performance parameters, making these needs transparent to all stakeholders, and solving for these needs by automating unit operations and managing all human workflows including training, SOPs, and troubleshooting. By doing so, it helps ensure continuous and efficient operation of these plants, reducing energy, breakdown, manpower, and chemical costs to the tune of ~25 to 35% over current costs.”

Digital Paani is currently working with more than 40 wastewater treatment plants. In the previous financial year (2023-24) till February 2024, they earned revenues of Rs 2.2 crore.

Looking ahead, Mansi says, “Our big ambition is to build the future of water and drive climate resilience by unlocking wastewater’s potential to be a key source of water globally. To do this, we intend to build the tech ecosystem for wastewater by not only working with 5,000 facilities in the next five years to ensure they operate well but also creating data products that replace the consultant industry that drives infrastructure decisions with a more data-driven approach. We also intend to enable each building and factory to be water-neutral.”

Meanwhile, Rajesh notes, “Our eventual vision is to create water-positive buildings and industries that in turn significantly improve quality of life in our cities.”

(Edited by Pranita Bhat; Images courtesy /Instagram, , )

She didn’t have to look any further than her father Rajesh Jain, a graduate of chemical engineering from the , who had spent the last 25 years in the water and energy industry developing hundreds of water treatment facilities across India.

Speaking to The Better India, Mansi recalls, “Incidentally, my father had been an engineer in the water and energy industry for over 25 years, and designed as well as operated over 400 wastewater treatment facilities in India with the consistent takeaway that 75% of these facilities failed operationally even though they were key to the local water ecosystem.”

Managing Water Treatment Infrastructure: Mansi Jain, co-founder of Digital Paani

But why do these facilities fail?

According to Mansi, most of these plants don’t work in the long run for a variety of reasons including biological disturbance, equipment failure like burnt pumps, or the choking of membrane filters that act as a barrier to separate contaminants from the water.

So, is there a way for these plants to anticipate these problems and fix them in advance to improve their efficiency and longevity? Suffice it to say that there are a variety of today that are developing technological solutions for wastewater management.

“India has about 90,000 installed wastewater treatment plants. But today 95% of the market is managed entirely manually by deploying operators in each plant. This has several drawbacks; problems are detected about three weeks late after breakdowns and operators lack the expertise to tackle problems. Other technologies in the market only make dents in part of the problem; they only monitor data or automate the key equipment like pumps,” she says.

After months of brainstorming to understand how they can solve this problem in a scalable manner, they started Digital Paani in end 2020, piloted an IoT-enabled software that manages end-to-end operations of a water treatment plant, and saw “incredible results”.

Digital Paani is helping buildings and industries move towards water neutrality and reduce water losses across their campus. To do this, Digital Paani works in a stepwise manner:

1) Maximise recycling by ensuring wastewater infrastructure is working well.

2) Helping industries and residential societies do water accounting real-time, know where they are having water losses, and provide roadmaps to reduce those losses.

3) Actually reducing those losses by providing operational excellence and management through technology for key assets contributing to water losses such as cooling towers.

In other words, Digital Paani is a water management platform that tracks and manages a water treatment plant’s health and performs tasks like equipment automation, providing WhatsApp updates to users, and guiding process management.

By offering real-time insights, complete control, and 24/7 management with actionable recommendations, they drive operational excellence for sustainable water management.

As Mansi explains, “Think of our platform as a doctor for water infrastructure, telling buildings what’s wrong with their infrastructure and what it needs, as well as providing the medicine to fix it, whether it’s directing technicians on about the right amount of chemical dosage required, automating equipment to function properly or directing operators on the best next steps. Through our work, we help clients save crores in fines, but more importantly, they recycle their wastewater — 90 million litres of wastewater is treated daily at plants associated with us.”

At present, over 40 industry giants, including Tata Power, Delhi Jal Board, Britannia, and Leela Hotels, are using the Gurugram-based startup’s technology.

Understanding the elements that Digital Paani works with to address their water treatment needs.

Unlocking business and product innovation

“Once we log in design inputs about the infrastructure into our software, we create standard operating procedures for operating the plant in real-time. Our client can visualise the asset (wastewater treatment plant) and can gauge its analytics from how much wastewater is getting treated to the quality of treatment being achieved and whether the equipment is functioning properly or not,” said Mansi during an episode of in April 2024.

“In other words, the client has a complete online software before them to visualise their asset. If there is a problem inside the plant, our software can assess and interpret data using AI to detect it. The best part is that clients don’t even have to be on our software to manage these issues. Management actions are happening automatically, whether through equipment control or by telling operators directly what to do. Clients just receive alert notifications on their WhatsApp number to make things easy,” she added.

Their product innovation, Mansi argues, also allows them to unlock business model innovation. “Instead of becoming an add-on cost for facilities like our competitors, we can de-risk adoption and offer guaranteed savings through two models which no one else in the market can do,” says Mansi, speaking to The Better India.

“First, we enable plant owners to manage plants using their under-utilised staff like electricians with our system and team’s remote management rather than outsourcing operations for lack of expertise. This allows them to save up to 66% of operating costs,” she adds.

Second, as Rajesh notes, “We take the entire operations contract of a facility and allow service provider partners that provide physical services like operators onsite to manage clusters of plants as a fleet with a small common workforce rather than individual deployments.”

How does Digital Paani work?

Digital Paani “integrates every aspect of wastewater treatment operations and scales the expertise needed to handle facilities” in three steps.

1) First, it ‘knows’ the needs of the plants by determining how each facility should operate given its unique physical configuration and needs. “We do this by doing a design assessment of each facility on our software as well as capturing operations information from each unit operation in a facility. This data spans a wide range, from using computer vision to look at biological process health, to looking at electrical data, energy data, pressure, vibration, flow, etc,” says Mansi.

2) Second, it ‘tells’ the need to the relevant stakeholders by offering complete visibility through WhatsApp and live dashboards.

3) Finally, it ‘solves’ the need by executing the required actions directly through automated workflows, whether it is training onsite teams, guiding their daily workflow and validating their work or managing the physical operation of equipment through our in-platform automation manager. When things start going wrong, it uses data streams from onsite sensors and electrical panels to diagnose the root cause of the issue and drive issue closure.

“We even recommend operational and physical improvements. This approach has transformed defunct facilities while reducing their costs by up to 66%,” claims Rajesh.

Digital Paani looks to understand the physical water treatment infrastructure and develops unique tools to manage it.

How do industry giants use Digital Paani?

Mansi argues that every building and factory can rely on local and renewable wastewater for up to 90% of their water needs, a vital response to amid climate change. Unfortunately, as she stated earlier in this article, about 75% of treatment facilities end up dysfunctional because operations are manual and reactive, and the expertise and skills needed to manage such complex operations don’t exist at the ground level.

“We’re solving the above issue by reimagining this industry through Digital Paani, which effectively scales the needed technical expertise to drive operational excellence in facilities. This results in the transformation of non or low-functioning plants to high-quality, compliant units treating 100% of water to high-water-quality standards, all while reducing operating costs by up to 30%. Many of our customers have been able to reduce breakdowns significantly (up to 85%) and reduce energy consumption in the range of 20 to 35%,” she claims.

“Most importantly, they can now confidently reuse this water; many of our customers have gone from reusing 45% of their water on average to around 80%. This is why major players in the industry are adopting our technology,” she adds.

Moreover, as Mansi notes, the ease of integrating Digital Paani, which functions on a plug-and-play model, “further enhances its appeal”. Treatment facilities of any size and type can be installed in three straightforward steps:

1) Site survey

2) [Parallel] Any IoT deployment needed on the ground

3) [Parallel] Plant onboarding onto our software

“This whole process only takes 30 to 45 days,” she says.

Besides industries, Digital Paani has also made forays into the residential sector.

“We provide continuous expertise for regular operations as well as guidance on the needed retrofits so that they can get their STP completely streamlined and treat and reuse their water. We have converted many residential STPs from dysfunctional to reusing 70% of water in flushing, horticulture, and more. Many customers used to receive notices and fines from the Pollution Control Board earlier because they were unable to manage their operations, and we have solved that for good,” she claims.

Adaptable to different environments

“Our software is highly flexible, featuring comprehensive configuration panels that simplify the integration of plants of different sizes and technologies. On the backend, we have onboarded each key unit operation in water management, be it biological treatment, chemical treatment, RO systems, UF systems or more, so when we onboard a new unit, we simply tick that module and get the relevant analytics, automation flows, alerts, and so on,” says Rajesh.

“This makes it easy to adapt to facilities of all kinds. Moreover, our team is well-equipped to provide expert support for any plant management as required. For instance, at present, we serve diverse needs including STP management for Taj Hotels, ETP management for Britannia, total water management for Plaksha University, and a 70 MLD STP in Dwarka, Delhi,” he adds.

Mansi Jain and her father Rajesh recently appeared on Shark Tank India.

Pan-India presence and funding their ambition

Digital Paani is currently operational in about 14 states and has raised about $1.2 million from global investors like Elemental Excelerator and Echo River Capital as well as Indian investors like Enzia, Peer Cheque, SAE, DevC, Bharat Founders Fund, and leading angels like Ashish Goel (Urban Ladder), Yamini Bhatt (Wymo) and Mohit Tandon (Delhivery).

As Karuna Jain and Shivam Jindal of Enzia Ventures, a venture capital fund, in the startup, “Digital Paani’s solution seamlessly integrates into existing facilities, analysing the infrastructure’s needs based on multiple performance parameters, making these needs transparent to all stakeholders, and solving for these needs by automating unit operations and managing all human workflows including training, SOPs, and troubleshooting. By doing so, it helps ensure continuous and efficient operation of these plants, reducing energy, breakdown, manpower, and chemical costs to the tune of ~25 to 35% over current costs.”

Digital Paani is currently working with more than 40 wastewater treatment plants. In the previous financial year (2023-24) till February 2024, they earned revenues of Rs 2.2 crore.

Looking ahead, Mansi says, “Our big ambition is to build the future of water and drive climate resilience by unlocking wastewater’s potential to be a key source of water globally. To do this, we intend to build the tech ecosystem for wastewater by not only working with 5,000 facilities in the next five years to ensure they operate well but also creating data products that replace the consultant industry that drives infrastructure decisions with a more data-driven approach. We also intend to enable each building and factory to be water-neutral.”

Meanwhile, Rajesh notes, “Our eventual vision is to create water-positive buildings and industries that in turn significantly improve quality of life in our cities.”

(Edited by Pranita Bhat; Images courtesy /Instagram, , )