Like most things mobility, the future of air transport is also electric. There has been a significant push by the aviation industry to decarbonise air transport given the myriad ways it pollutes the environment including

and noise pollution. (Image above of Dr Feroz Ahmed, aerospace engineer)

Today, you have eVTOLs (electric Vertical Take-Off and Landing aircraft), sometimes referred to as air taxis or flying taxis, like the Lilium Jet — a prototype eVTOL designed by Lilium GmbH, a German aerospace company. Unlike conventional aeroplanes, eVTOLs fly like helicopters and typically carry anywhere between two to six passengers, including a pilot.

Apart from eVTOLs, there are aircrafts like the E9X — a prototype electric aircraft designed by Dutch aviation startup Elysian, which they claim can hold 90 passengers and fly up to 500 miles without having to stop to recharge. According to ABC News, E9X is expected to be in service by 2033. There is also the NOVA developed by ONERA, the French national aerospace research centre, which they claim is designed to carry 180 passengers on 3,000 nautical miles and is expected to be in service by 2030.

Lilium static demonstrator at EBACE 2023 at Palexpo, Le Grand-Saconnex (Image courtesy Wikimedia Commons)

Suffice it to say, there is a growing demand for these modern urban air mobility (UAM) systems that aim to offer a pleasant flight experience while minimising carbon footprint. Regulatory and governing bodies around the world like the European Commission have taken note of this demand. In its Flight Path 2050 (FP250) challenge, the European Commission has set ambitious targets for future commercial transport aircraft, including a reduction of CO2 emissions by 75%, NOx emissions by 95%, and noise emissions by 65% by the year 2050.

While these modern UAM systems address carbon emissions with reliance on electric batteries rather than fossil fuels, the challenge of nose emission remains unresolved.

Speaking to The Better India, Dr Feroz Ahmed, a Ladakhi aerospace engineer and Senior Research Associate at the University of Bristol, says, “Although electric engines are generally quieter than their combustion counterparts, the overall noise levels of UAM systems can still be significant due to factors like rotor/fan/propeller noise and the frequency of operations near populated areas.”

“However, the challenge of remains significant, as it impacts community health, disrupts wildlife, and is critical for gaining regulatory and public acceptance. Therefore, despite advancements in emission reductions, the aviation industry must also prioritise developing technologies to reduce noise levels to ensure the broader acceptance and success of new aircraft technologies, including modern UAM systems,” adds the 35-year-old.

For representational purposes only: Conventional air travel pollutes the environment (Image courtesy Freerange Stock)

Conventional commercial aeroplanes are quite noisy mainly because of two types of noise from their engines: mechanical noise and aerodynamic noise.

“Mechanical noise comes from moving parts inside the engine, such as gears, rotors, turbines, and combustion chambers. This noise also includes sounds from imbalances when these parts don’t spin perfectly, causing vibrations. Aerodynamic noise is created because of how the air moves around and through the engine. As the engine’s fan blades spin rapidly, they chop through the air, which can be noisy. Plus, when air rushes over the engine’s surfaces and other parts of the aeroplane at high speeds, it generates even more noise, similar to the loud whoosh you hear when you stick your hand out of a moving car window,” explains Dr Ahmed.

“However, in future electric aeroplanes, mechanical noise will be significantly reduced because these aircrafts will rely on electric motors, which have fewer moving parts like gears, rotors, and turbines. This means there will be less vibration and fewer sources of imbalance-related noise. But aerodynamic noise will still be present, as the movement of air around the aircraft and through any fans or propellers used to generate lift and propulsion will continue to create noise,” he adds.

Earlier this year in April, Dr Feroz Ahmed and his team at the University of Bristol’s School of Civil, Aerospace and Design Engineering, published a breakthrough study in the Journal of Fluid Mechanics that “reveals for the first time” how noise is generated and propagated from boundary layer ingesting (BLI) ducted fans featuring in modern electric UAM systems, thus possibly paving the way for a future of silent flights.

He explains, “BLI ducted fans, also known as embedded engines, are similar to large engines found in modern aeroplanes but are partially embedded into the plane’s main body instead of under the wings far from the main body. As they ingest air from both the front and from the surface of the airframe, they don’t have to work as hard to move the plane, so it burns less fuel.”

Writing for Aerospace Testing International, Dr Ahmed notes, “Electric ducted fan propulsion systems are gaining significant attention for their potential to help power next-generation aircraft toward Net Zero emissions. These systems are typically mounted in two ways, away from the airframe, or close to or embedded within the airframe. The latter are known as boundary layer ingesting (BLI) ducted fans and operate adjacent to the fuselage or wing, ingesting the boundary layer flow. This technology is integral to several future aircraft, such as ONERA’s NOVA, the NASA/MIT Aurora D8, Airbus’ Nautilus and the Lilium Jet.”

So, what does the groundbreaking study his team recently published in the Journal of Fluid Mechanics say?

As Dr Ahmed explains, “Our study at the University of Bristol’s National Aeroacoustic Wind Tunnel Facility revealed the fundamental mechanisms of noise generation from these BLI ducted fans. We were able to identify distinct noise sources originating from the duct, the rotating fan, and the air flowing over the curved airframe surface.”

“We found that the noise pattern changes depending on how much thrust the fan is producing. When the fan is producing high thrust, we observed a noise pattern similar to what is seen in fans without ducts. But when the fan is producing less thrust, the noise pattern changes because the duct itself starts making more noise. By understanding the source of noise from our research, engineers can decide what aspects of noise to be controlled and they can make effective noise control devices accordingly,” he adds.

By understanding the noise mechanisms in BLI ducted fans, Dr Ahmed also hopes that industrial guidelines can be developed for “quieter airframe-integrated propulsion systems in future aircraft concepts” from large-scale conventional aircraft to small-scale eVTOL aircrafts.

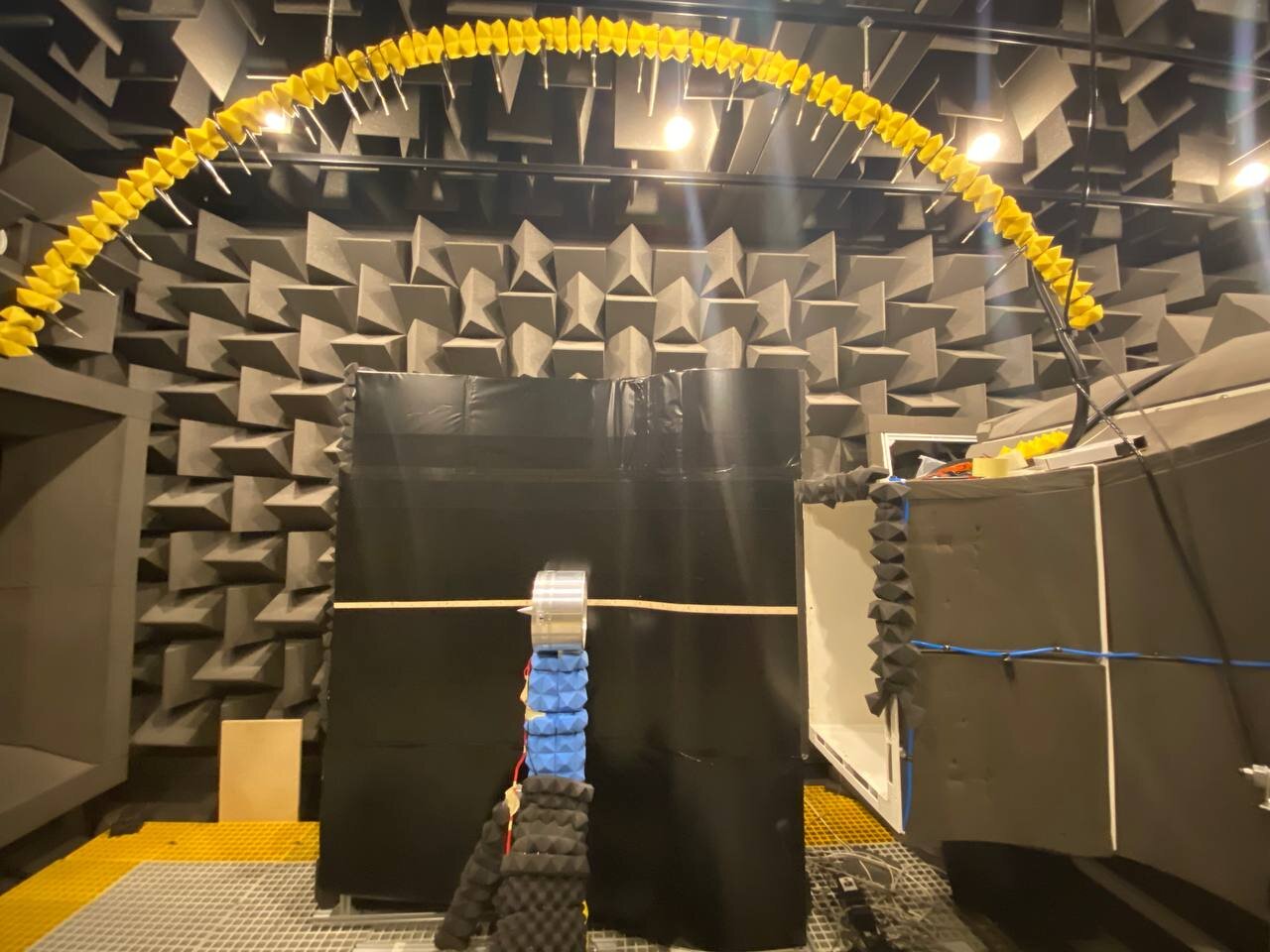

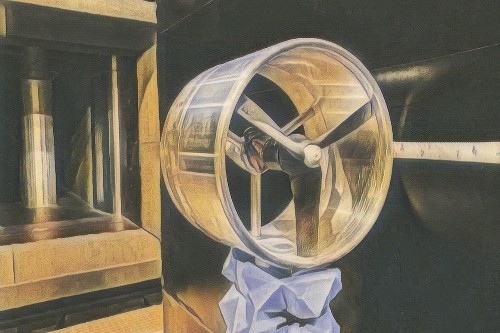

Electric ducted fan mounted next to the curved surface

“Identifying the physical sources of noise is crucial for effective noise reduction. For noise reduction purposes, we must find out what the physical sources are,” he says.

“Thus far, it appears that noise suppression methods or devices in ducted fans have been developed largely on a trial and error basis. It is hoped that future efforts in ducted fan noise suppression will focus on suppressing both fan and duct noise in both high and low-thrust regimes. By advancing our understanding of these noise sources, we hope to contribute to the development of more precise noise guidelines and standards, thereby simplifying the certification process for future aircraft technologies,” he adds.

The research, led by Dr Feroz Ahmed, was organised under the supervision of Professor Mahdi Azarpeyvand. It was sponsored by the European Union’s Horizon 2020 research and innovation programme under the ENODISE (Enabling optimised disruptive airframe-propulsion integration concepts) project in collaboration with ONERA, and other partners.

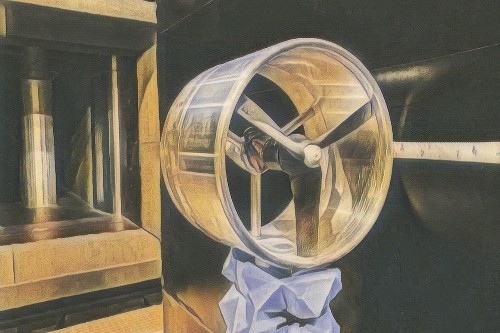

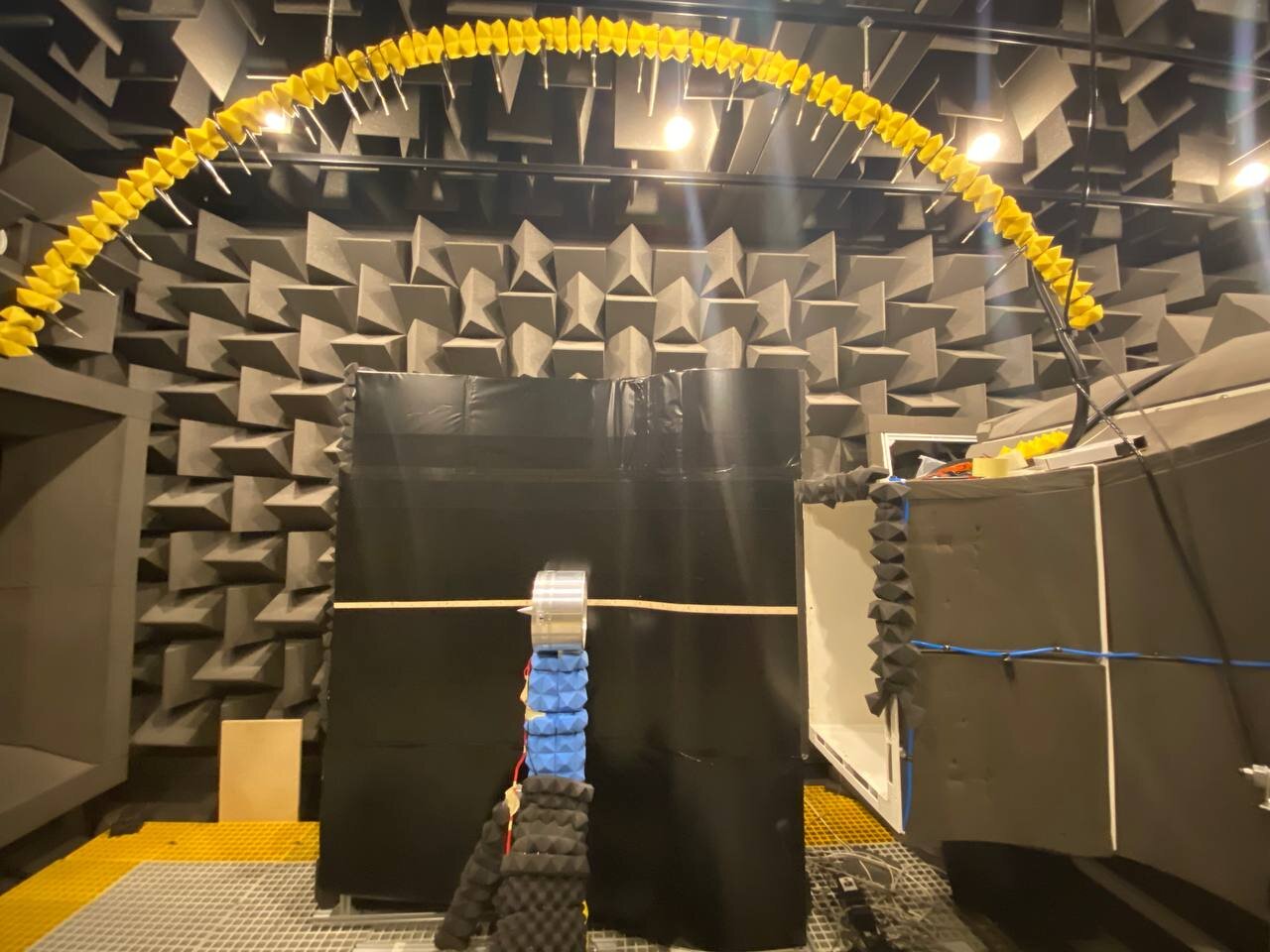

Boundary layer ingesting (BLI) ducted fan test rig inside the aeroacoustics wind tunnel facility at the University of Bristol

Growing up in a family with modest means in , Dr Ahmed never thought in a million years that he would one day be working on groundbreaking research projects in modern aviation.

His parents, Haji Haleem and Zahra Bano, were originally from Kargil but moved to Leh in the early 1980s in search of better livelihood opportunities. In the Skampari area of Leh, Dr Ahmed grew up alongside children from other migrant communities from Kargil and Nubra.

Despite being (formally) illiterate, his parents were committed to ensuring that Dr Ahmed and his six siblings received a quality education.

“My father started as a construction labourer, taught himself mathematics and gradually worked his way up to supervisor before eventually becoming a construction contractor in Leh. I was born when my father was transitioning from construction supervisor to contractor,” he recalls.

His father’s journey, achieved without any formal education, deeply inspired him. During Dr Ahmed’s childhood, his father often took him to construction sites on weekends. There, he was exposed to practical engineering and interacted closely with workers and engineers.

“These memorable experiences greatly influenced my early academic development, particularly my passion for mathematics and physics. I credit this early exposure and my father’s inspiring journey for my strong foundation in these subjects,” he notes.

Meanwhile, his interest in becoming an aerospace engineer developed while he was studying in Leh and Jammu. “Unlike other students, I didn’t want to take the conventional route in engineering. Most students end up going for electrical, civil or but I wanted to explore something different and aerospace engineering caught my interest,” he says.

After obtaining his undergraduate degree in Aeronautical Engineering at Punjab Engineering College (PEC) Chandigarh in 2012, he was selected to study at the Bengaluru, for his master’s degree in Aerospace Engineering. For his master’s thesis, he did research on a Reusable Launch Vehicle (RLV) using experiments in wind tunnels. His thesis was supported by the Indian Space Research and Development Organisation (ISRO).

Dr Ahmed’s time at IISc was a turning point. His thesis was awarded an outstanding grade (awarded 8/8 GPA), and the research outcome was later published and presented at an international conference. He credits his thesis supervisor Dr SB Kandagal at IISc for moulding him into a good researcher.

“The profound journey at IISc showed me the way to move forward towards research, and most importantly, it was at this institution where I discovered my passion for solving problems in complex engineering systems,” he recalls.

After completing his master’s, Dr Ahmed spent four years in the aerospace industry and academia as an engineer and assistant professor in Bengaluru, further expanding his skills and practical knowledge. His growing interest in conducting deeper research led him to pursue a PhD in the . In 2018, he was accepted into a competitive four-year doctoral programme at University College London (UCL).

British Petroleum, a British multinational oil and gas company, and the Engineering and Physical Science Research Council (EPSRC) of the United Kingdom funded his PhD through the Industrial Cooperative Awards in Science & Technology (iCASE) programme. To cover his tuition fees and monthly salaries, a scholarship of £180,000 was awarded to him.

Dr Ahmed completed his PhD in September 2022, marking a significant milestone in his career as a researcher and engineer, ready to contribute innovative solutions to the field of aerospace engineering. Based on high-quality research output during his PhD, he was granted a United Kingdom Global Talent visa, endorsed by UK Research and Innovation (UKRI) and started working as a researcher at the University of Bristol on 1 October 2022.

“Although institutions in India opened many doors for me, my research work took off in the UK. I feel more work needs to be done to support and encourage quality research work in India. There are many scientists and engineers from underprivileged and underrepresented communities like me in the country who have the talent to do high-quality research but don’t have the requisite environment, and social and institutional support,” he says.

(Edited by Pranita Bhat; Images courtesy Dr Feroz Ahmed, Wikimedia Commons and University of Bristol)

Today, you have eVTOLs (electric Vertical Take-Off and Landing aircraft), sometimes referred to as air taxis or flying taxis, like the Lilium Jet — a prototype eVTOL designed by Lilium GmbH, a German aerospace company. Unlike conventional aeroplanes, eVTOLs fly like helicopters and typically carry anywhere between two to six passengers, including a pilot.

Apart from eVTOLs, there are aircrafts like the E9X — a prototype electric aircraft designed by Dutch aviation startup Elysian, which they claim can hold 90 passengers and fly up to 500 miles without having to stop to recharge. According to ABC News, E9X is expected to be in service by 2033. There is also the NOVA developed by ONERA, the French national aerospace research centre, which they claim is designed to carry 180 passengers on 3,000 nautical miles and is expected to be in service by 2030.

Lilium static demonstrator at EBACE 2023 at Palexpo, Le Grand-Saconnex (Image courtesy Wikimedia Commons)

Suffice it to say, there is a growing demand for these modern urban air mobility (UAM) systems that aim to offer a pleasant flight experience while minimising carbon footprint. Regulatory and governing bodies around the world like the European Commission have taken note of this demand. In its Flight Path 2050 (FP250) challenge, the European Commission has set ambitious targets for future commercial transport aircraft, including a reduction of CO2 emissions by 75%, NOx emissions by 95%, and noise emissions by 65% by the year 2050.

While these modern UAM systems address carbon emissions with reliance on electric batteries rather than fossil fuels, the challenge of nose emission remains unresolved.

Speaking to The Better India, Dr Feroz Ahmed, a Ladakhi aerospace engineer and Senior Research Associate at the University of Bristol, says, “Although electric engines are generally quieter than their combustion counterparts, the overall noise levels of UAM systems can still be significant due to factors like rotor/fan/propeller noise and the frequency of operations near populated areas.”

“However, the challenge of remains significant, as it impacts community health, disrupts wildlife, and is critical for gaining regulatory and public acceptance. Therefore, despite advancements in emission reductions, the aviation industry must also prioritise developing technologies to reduce noise levels to ensure the broader acceptance and success of new aircraft technologies, including modern UAM systems,” adds the 35-year-old.

For representational purposes only: Conventional air travel pollutes the environment (Image courtesy Freerange Stock)

Understanding noise pollution in aviation

Conventional commercial aeroplanes are quite noisy mainly because of two types of noise from their engines: mechanical noise and aerodynamic noise.

“Mechanical noise comes from moving parts inside the engine, such as gears, rotors, turbines, and combustion chambers. This noise also includes sounds from imbalances when these parts don’t spin perfectly, causing vibrations. Aerodynamic noise is created because of how the air moves around and through the engine. As the engine’s fan blades spin rapidly, they chop through the air, which can be noisy. Plus, when air rushes over the engine’s surfaces and other parts of the aeroplane at high speeds, it generates even more noise, similar to the loud whoosh you hear when you stick your hand out of a moving car window,” explains Dr Ahmed.

“However, in future electric aeroplanes, mechanical noise will be significantly reduced because these aircrafts will rely on electric motors, which have fewer moving parts like gears, rotors, and turbines. This means there will be less vibration and fewer sources of imbalance-related noise. But aerodynamic noise will still be present, as the movement of air around the aircraft and through any fans or propellers used to generate lift and propulsion will continue to create noise,” he adds.

Earlier this year in April, Dr Feroz Ahmed and his team at the University of Bristol’s School of Civil, Aerospace and Design Engineering, published a breakthrough study in the Journal of Fluid Mechanics that “reveals for the first time” how noise is generated and propagated from boundary layer ingesting (BLI) ducted fans featuring in modern electric UAM systems, thus possibly paving the way for a future of silent flights.

He explains, “BLI ducted fans, also known as embedded engines, are similar to large engines found in modern aeroplanes but are partially embedded into the plane’s main body instead of under the wings far from the main body. As they ingest air from both the front and from the surface of the airframe, they don’t have to work as hard to move the plane, so it burns less fuel.”

Writing for Aerospace Testing International, Dr Ahmed notes, “Electric ducted fan propulsion systems are gaining significant attention for their potential to help power next-generation aircraft toward Net Zero emissions. These systems are typically mounted in two ways, away from the airframe, or close to or embedded within the airframe. The latter are known as boundary layer ingesting (BLI) ducted fans and operate adjacent to the fuselage or wing, ingesting the boundary layer flow. This technology is integral to several future aircraft, such as ONERA’s NOVA, the NASA/MIT Aurora D8, Airbus’ Nautilus and the Lilium Jet.”

So, what does the groundbreaking study his team recently published in the Journal of Fluid Mechanics say?

As Dr Ahmed explains, “Our study at the University of Bristol’s National Aeroacoustic Wind Tunnel Facility revealed the fundamental mechanisms of noise generation from these BLI ducted fans. We were able to identify distinct noise sources originating from the duct, the rotating fan, and the air flowing over the curved airframe surface.”

“We found that the noise pattern changes depending on how much thrust the fan is producing. When the fan is producing high thrust, we observed a noise pattern similar to what is seen in fans without ducts. But when the fan is producing less thrust, the noise pattern changes because the duct itself starts making more noise. By understanding the source of noise from our research, engineers can decide what aspects of noise to be controlled and they can make effective noise control devices accordingly,” he adds.

By understanding the noise mechanisms in BLI ducted fans, Dr Ahmed also hopes that industrial guidelines can be developed for “quieter airframe-integrated propulsion systems in future aircraft concepts” from large-scale conventional aircraft to small-scale eVTOL aircrafts.

Electric ducted fan mounted next to the curved surface

“Identifying the physical sources of noise is crucial for effective noise reduction. For noise reduction purposes, we must find out what the physical sources are,” he says.

“Thus far, it appears that noise suppression methods or devices in ducted fans have been developed largely on a trial and error basis. It is hoped that future efforts in ducted fan noise suppression will focus on suppressing both fan and duct noise in both high and low-thrust regimes. By advancing our understanding of these noise sources, we hope to contribute to the development of more precise noise guidelines and standards, thereby simplifying the certification process for future aircraft technologies,” he adds.

The research, led by Dr Feroz Ahmed, was organised under the supervision of Professor Mahdi Azarpeyvand. It was sponsored by the European Union’s Horizon 2020 research and innovation programme under the ENODISE (Enabling optimised disruptive airframe-propulsion integration concepts) project in collaboration with ONERA, and other partners.

Boundary layer ingesting (BLI) ducted fan test rig inside the aeroacoustics wind tunnel facility at the University of Bristol

From Ladakh to Bristol

Growing up in a family with modest means in , Dr Ahmed never thought in a million years that he would one day be working on groundbreaking research projects in modern aviation.

His parents, Haji Haleem and Zahra Bano, were originally from Kargil but moved to Leh in the early 1980s in search of better livelihood opportunities. In the Skampari area of Leh, Dr Ahmed grew up alongside children from other migrant communities from Kargil and Nubra.

Despite being (formally) illiterate, his parents were committed to ensuring that Dr Ahmed and his six siblings received a quality education.

“My father started as a construction labourer, taught himself mathematics and gradually worked his way up to supervisor before eventually becoming a construction contractor in Leh. I was born when my father was transitioning from construction supervisor to contractor,” he recalls.

His father’s journey, achieved without any formal education, deeply inspired him. During Dr Ahmed’s childhood, his father often took him to construction sites on weekends. There, he was exposed to practical engineering and interacted closely with workers and engineers.

“These memorable experiences greatly influenced my early academic development, particularly my passion for mathematics and physics. I credit this early exposure and my father’s inspiring journey for my strong foundation in these subjects,” he notes.

Meanwhile, his interest in becoming an aerospace engineer developed while he was studying in Leh and Jammu. “Unlike other students, I didn’t want to take the conventional route in engineering. Most students end up going for electrical, civil or but I wanted to explore something different and aerospace engineering caught my interest,” he says.

After obtaining his undergraduate degree in Aeronautical Engineering at Punjab Engineering College (PEC) Chandigarh in 2012, he was selected to study at the Bengaluru, for his master’s degree in Aerospace Engineering. For his master’s thesis, he did research on a Reusable Launch Vehicle (RLV) using experiments in wind tunnels. His thesis was supported by the Indian Space Research and Development Organisation (ISRO).

Dr Ahmed’s time at IISc was a turning point. His thesis was awarded an outstanding grade (awarded 8/8 GPA), and the research outcome was later published and presented at an international conference. He credits his thesis supervisor Dr SB Kandagal at IISc for moulding him into a good researcher.

“The profound journey at IISc showed me the way to move forward towards research, and most importantly, it was at this institution where I discovered my passion for solving problems in complex engineering systems,” he recalls.

After completing his master’s, Dr Ahmed spent four years in the aerospace industry and academia as an engineer and assistant professor in Bengaluru, further expanding his skills and practical knowledge. His growing interest in conducting deeper research led him to pursue a PhD in the . In 2018, he was accepted into a competitive four-year doctoral programme at University College London (UCL).

British Petroleum, a British multinational oil and gas company, and the Engineering and Physical Science Research Council (EPSRC) of the United Kingdom funded his PhD through the Industrial Cooperative Awards in Science & Technology (iCASE) programme. To cover his tuition fees and monthly salaries, a scholarship of £180,000 was awarded to him.

Dr Ahmed completed his PhD in September 2022, marking a significant milestone in his career as a researcher and engineer, ready to contribute innovative solutions to the field of aerospace engineering. Based on high-quality research output during his PhD, he was granted a United Kingdom Global Talent visa, endorsed by UK Research and Innovation (UKRI) and started working as a researcher at the University of Bristol on 1 October 2022.

“Although institutions in India opened many doors for me, my research work took off in the UK. I feel more work needs to be done to support and encourage quality research work in India. There are many scientists and engineers from underprivileged and underrepresented communities like me in the country who have the talent to do high-quality research but don’t have the requisite environment, and social and institutional support,” he says.

(Edited by Pranita Bhat; Images courtesy Dr Feroz Ahmed, Wikimedia Commons and University of Bristol)